“South Crofty is not just an old operation, but a new project leveraged with existing infrastructure”

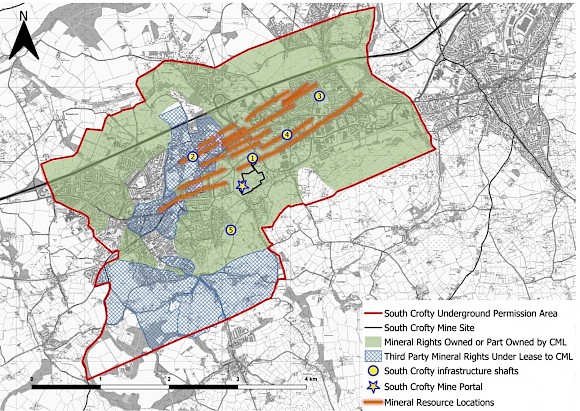

Cornish Metals is working towards re-opening the historic South Crofty underground tin mine, one of the highest-grade tin resources globally with potential to become a new, low-cost global producer. Cornish Metals is currently advancing South Crofty’s re-opening through mine dewatering, continued resource drilling as well as evaluating additional downstream opportunities. The 100% owned and fully permitted South Crofty tin project is a strategic tin asset and is located in the Central Mining District of Cornwall, in the towns of Pool and Camborne, UK.

Tin mining in this region dates back to 2,300 B.C. Large-scale production at South Crofty first started in the mid-1600s (the first documented production dated in 1592). The mine has been in operation intermittently since then, with the last closure in 1998 coming after a prolonged period of depressed tin prices. Historical production between 1700 to 1998 totalled over 450,000 tonnes of tin from the Central Mining District.

In March 2016, Cornish Metals entered into an agreement with Galena Special Situations Fund and Tin Shield Production Inc. to acquire a 100% interest in Western United Mines Ltd. (“WUML”) and Cornish Minerals Limited (Bermuda) (the "Companies"), which owned the South Crofty tin project plus additional mineral rights over a further 7,500 hectares located in various parts of Cornwall. The closing of the acquisition was announced on July 12, 2016.

The South Crofty project is fully permitted, having underground permission (mining licence) valid until 2071, planning permission to construct a new process plant and a permit from the Environment Agency to dewater the mine. Cornish Metals commissioned its Water Treatment Plant to dewater the mine in Q4 2023.

The underground permission area covers 1,490 hectares and includes 26 former producing mines. Current infrastructure on the property includes four usable vertical shafts and a 300 metre decline. Regional infrastructure includes excellent access to power, roads and rail. The process plant site is adjacent to the railway line and accessible grid power crosses the property. South Crofty mineralisation occurs in laterally extensive lode structures, with some over four kilometres ("km") long and extending to a vertical depth of at least 1,000 meters.

2024 Preliminary Economic Assessment

In 2024, Cornish Metals announced the results of the PEA for the South Crofty Tin Project. The PEA validates South Crofty's economic viability, producing a base case after-tax Net Present Value of US$201 million and Internal Rate of Return of 29.8%, and confirms the Project's potential to be a low-cost and long-life tin mining operation with a current 14-year mine life. South Crofty is expected to produce a clean, high-grade tin concentrate and to be an important tin producer in Europe, supplying into the growing demand for this critical metal that is essential for the energy transition.

Key Points

- 49,310 tonnes of tin metal in concentrate produced over a 14-year LOM

- Average annual tin production of 4,700 tonnes in years 2 through 6

- Average LOM processed tin head grade of 1.83%, upgraded from average mined grade of 0.94% through use of X-Ray Transmission ore sorting and Dynamic Dense Media Separation

- US$201 million After-tax NPV8% and 29.8% IRR at a base case tin price of US$31,000 /tonne

- Capital payback period of 3 years after-tax

- Pre-production capital of US$177 million

- LOM average all-in sustaining cost of US$13,700 /tonne

- Total after-tax cash flow generation of US$626 million from start of production, peaking at US$82 million in the second year of production

- Potential to directly employ over 300 people with permanent high skilled and well paid jobs and create up to 1,000 indirect jobs

- Growth opportunities from additional in-mine and near-mine exploration with the potential to extend the mine life and increase production

The full South Crofty PEA Technical report can be found here.

2023 NI 43-101 Updated Mineral Resource Estimate

In 2020, Cornish Metals ran a "proof of concept" drill programme designed to demonstrate the ability to infill drill the current resource from surface, to intersect multiple lodes from single drill holes and to demonstrate that the potential exists to materially increase the current resource. The results confirmed the high-grade nature and persistence of the known mineralised structures within South Crofty. Furthermore, it demonstrated management’s belief in the exploration potential at South Crofty to materially increase the existing Mineral Resource base.

In September 2023 the Company released an updated JORC (2012) Mineral Resource Estimate (“MRE”) for the South Crofty Tin Project. The focus of this new MRE is the Lower Mine area (“Lower Mine”) tin-only section of the Project, which has been subject to a thorough review, including further digitisation and modelling of historical data, but the Upper Mine polymetallic area has also been reported using current metal prices.

Furthermore, assay results from drilling of the existing major structures at depth (No.4, No.8, Roskear and North Pool Zone) as part of a metallurgical testwork programme, have been incorporated into the MRE.

Key Points

- 39.0% increase in tonnes and 31.6% increase in contained tin in the Indicated Mineral Resource category from the 2021 MRE;

- 35.6% increase in tonnes and 15.5% increase in contained tin in the Inferred Mineral Resource category from the 2021 MRE;

- This MRE is based on a 0.6% Sn cut-off grade, as was used in the 2021 MRE;

- The majority of new Mineral Resources are contained within the central part of the mine in No. 1, No. 2, No. 3, Main, Intermediate, North and Great Lodes following digitisation and modelling of historical data;

- The major lode structures that comprise the Mineral Resource remain open along strike and at depth;

- The MRE was prepared by Cornish Metals’ in-house geology team and independently reviewed and verified by Nicholas Szebor of AMC Consultants (UK) Ltd (“AMC”), who takes responsibility for the estimate.

The updated Mineral Resource Estimate (“MRE”) for South Crofty in accordance with the JORC Code (2012). The Mineral Resource is divided into the “Lower Mine” and “Upper Mine” areas for reporting purposes. A summary of the updated MRE is tabulated below:

|

South Crofty Summary (JORC 2012) Mineral Resource Estimate |

||||

|

Area |

Classification |

Mass (kt) |

Grade

|

Contained Tin / Tin Equivalent (kt) |

|

Lower Mine |

Indicated |

2,896 |

1.50% Sn |

43.6 |

|

Inferred |

2,626 |

1.42% Sn |

37.4 |

|

|

Upper Mine |

Indicated |

260 |

0.99% SnEq |

2.6 |

|

Inferred |

465 |

0.91% SnEq |

4.2 |

|

The 2023 Mineral Resource Estimate for South Crofty is available in a report titled the “South Crofty Tin Project - Mineral Resource Update NI 43-101 Technical Report”, dated October 27, 2023.

Infrastructure for Future Operations

Significant infrastructure for future operations is still intact.

Usable shafts (for ventilation and hoisting to a sub-level with connection to decline):

- New Cooks Kitchen: 770m deep 6.0m x 2.5m (principal production and service shaft)

- Roskear: 610m deep, 4.9m diameter

- Taylors: 520m deep, 6.0m x 3.0m

- Palmers: 500m deep, 2.5m x 1.8m

- Williams: 915m deep, 5.8m diameter

There is decline access available for future expansion and an area set aside for process plant construction, offices etc. with full extent planning permission. The process plant site is adjacent to a railway line with access to grid power.

Dewatering of South Crofty

The South Crofty mine workings are presently flooded, and dewatering is required prior to the potential reopening of the mine. Historic records indicate that about 6,500m3 of water enters the old workings on a daily basis. In March 2017, a water treatment trial was successfully completed at South Crofty and in October 2017 the Environment Agency granted a mine waste permit with water discharge consent to Cornish Metals that allowed treatment and discharge of up to 25,000m3/day of mine-water.

The new Water Treatment Plant was commissioned in October 2023 and mine dewatering commenced in November 2023. Prior to the commencement of the dewatering process, untreated mine water has naturally drained directly into the Red River. Cornish Metals is treating up to 25,000m3 of mine water per day at its Water Treatment Plant and removing substances such as iron, manganese and arsenic and greatly improving the quality of the water. Treated water is discharged into the Red River via the Dolcoath Deep Adit.

The Mine Water Treatment Plant at South Crofty - officially opened on October 26, 2023

Shared Prosperity Funded Projects

This project is part-funded by the UK Government through the UK Shared Prosperity Fund. Cornwall Council is responsible for managing projects funded by the UK Shared Prosperity Fund through the Cornwall and the Isles of Scilly Good Growth Programme.

Bartles Foundry Project

South Crofty Limited has been awarded up to £4,190,500 of Shared Prosperity Funding. The grant funding is equivalent to a maximum of 62% of the total Bartles Foundry project cost estimated at approximately £6.8 million for the construction of workshops, stores and offices at the Bartles Foundry site at South Crofty. This will support the requirements associated with South Crofty moving to production and includes the purchase of 4.5 acres of land from Cornwall Council on 1 April 2025. Conditional planning approval for the development was granted in January 2025 and this project follows on from the SPF part-funded study in 2024 which concluded that the Bartles Foundry site was suitable for development.